Sheet metal cold processing

Sheet metal cold forging

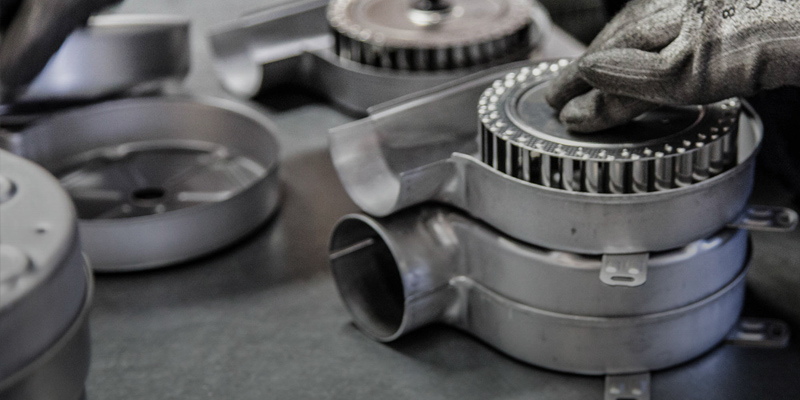

The moulding activity includes a series of mechanical operations through which, without having chip production, an object of any geometry can be obtained – flat or folded - starting from a flat sheet metal. In practice, the sheet metal is subjected to plastic deformation. These operations are carried out using moulds mounted on forging presses or special tools.

These processes are carried out with automatically fed hydraulic presses. The tonnage is 30 to 500 tons, using a 1000×4 mm belt. We can carry out deep drawing up to a height of 200 mm.

Other processes

done by us

We have twenty years of experience in sheet metal bending. It is a process of cold working of metals using the pressure exerted by a mould, and is used to obtain certain shapes.

We can carry out wire bending operations using 3 mm to 10 mm CNC machines.

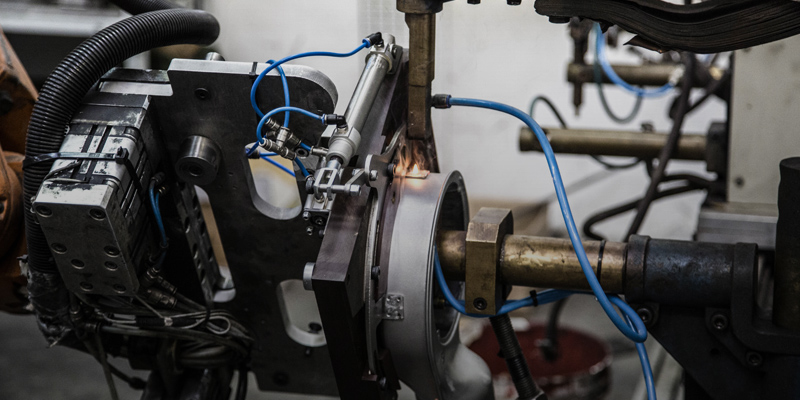

We can supply laser cut of any detail, size and thickness on any type of material or alloy.

We specialise in punching processes for sheet metal work performed by numerical control, ensuring the highest standards of quality.

We intend to deliver a complete service to our customers, thus delivering finished parts, so we can carry out all metal welding operations, both in an automated and a manual way.

We offer a turnkey service, that obviously is completed with the delivery of the finished product. So we also deal with product assembly and packaging.